Frequently Asked Questions

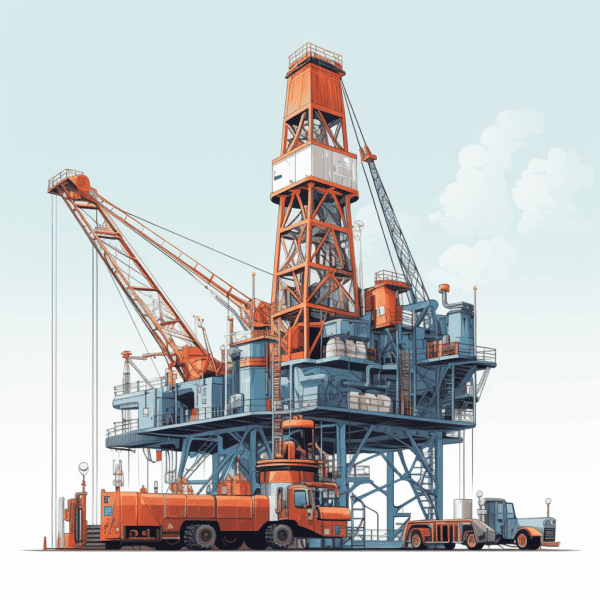

In the vast and intricate world of the oil and gas industry, understanding specific equipment and processes can be daunting for many. Wikipedia, the go-to source for quick definitions, describes a workover rig in the following manner: “The term workover is used to refer to any oil well intervention involving invasive techniques, such as wireline, […]

Read MoreAcid gas is a type of natural gas that contains significant quantities of hydrogen sulfide (H2S), carbon dioxide (CO2), or similar acidic gasses.

Read MoreGet answers to our client’s most frequently asked questions about our Fuel Gas Conditioning System (FCS)

Read MoreGet answers to our client’s most frequently asked questions about our Fuel Gas Conditioning System (FCS)

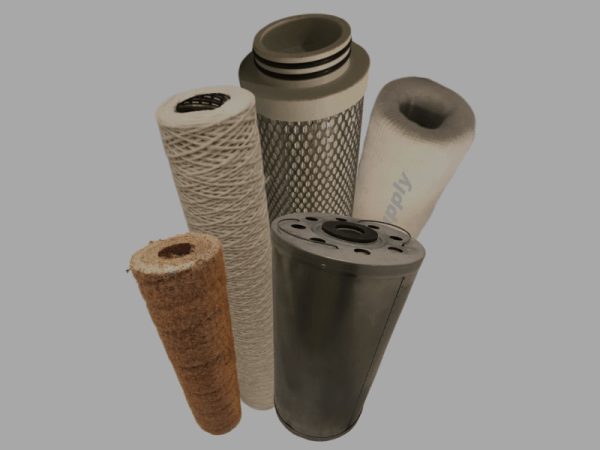

Read MoreGet answers to our client’s most frequently asked questions about filtration for amine plants, glycol dehydrators, and coalescing filters.

Read MoreCroft Production Systems offers skid-mounted Joule Thomson Systems that simultaneously reduces the water dew point of gas, recovers valuable hydrocarbon liquids, and lowers the BTU

Read MoreAmine Plant processing Acid Gas

Read MoreAbsorption vs. Adsorption Dehydrating natural gas, or the removal of water vapor from natural gas can be done by either adsorption or absorption. Croft’s Passive Dehydration System uses adsorption, where water vapor is collected and condensed on the surface with the use of a solid desiccant. Solid desiccants have a high adsorption capacity, a low resistance to gas […]

Read MoreRaw natural gas must be dehydrated to remove water vapor. Natural gas dehydration will eliminate the formation of hydrates and over-saturation of natural gas. All of these issues can cause corrosion, impacting the longevity of your gas processing equipment, and cause the gas stream to not meet pipeline specifications.

Read MoreCROFT Passive Dehydration Systems natural gas dehydration unit that utilizes a specially formulated solid desiccant called enviroDRI to adsorb water from the gas stream. Below are our clients’ most commonly asked questions about enviroDRI. What is enviroDRI? enviroDRI is a deliquescent desiccant pellet about the size of an almond designed to adsorb water from hydrocarbon […]

Read MoreThe Passive Dehydration System is the preferred alternative to the glycol unit for natural gas dehydration. Dehydration is a critical process required to meet pipeline specifications.

Read MoreOil storage tanks serve as a staging area to collect crude oil in several stages of production. These tanks are used in production fields and hold the oil until it is delivered to tankers or into a pipeline. Storage tanks are also used as a holding area for crude oil before the refining process and they also hold refined products after it is processed.

Read MoreCoalescing Filtration and Gas Separators: A Closer Look Separating contaminants from gas streams is vital for many industries to ensure product quality, operational efficiency, and environmental safety. Among the various technologies and equipment used for this purpose, coalescing filtration, often referred to as coalescing gas separators, stands out for its specific design aimed at eliminating […]

Read MoreCoalescing gas separators (or coalescing separators) are designed specifically for the removal of mist, fogs, and dust from gas streams. Standard separators cannot remove these small, minute contaminants in the gas stream because particles are usually less than 10 microns. A coalescing gas separator consist of a vessel, combining specially constructed coalescing elements and a […]

Read MoreA separator is a mechanical device for removing and collecting liquids from natural gas. Read our blog on What is a Separator? to learn more about the specific applications for a separator. Now, let’s dive in on the specifics of how a separator works and understanding the process a little more in-depth. The Separation Process: All separators […]

Read MoreAn oil and gas separator is used for removing and collecting liquids from natural gas. A properly designed separator will also provide the release of entrained gases from the accumulated hydrocarbon liquids. These separators can go by many names or different purposes like liquid separators, oil separators, water and oil separators, etc., but the most […]

Read MoreA bullet tank is a storage container that houses natural gas liquids (NGLs). The tanks come in many different sizes and include accessories that best suit your operation. Bullet tanks range from 6,000 to 30,000 gallons, with an 18,000-gallon tank being the most common size. Tanks should be no more than 70-80% full in order for […]

Read MoreJT systems are primarily used for NGL recovery, dew point specification for pipeline spec, and the reduction of the BTUs of the natural gas for natural gas-powered engines.

Read MoreRecently, I took a class along with some tests and bam! I got a safety certification! Specifically in the oil & gas industry of course. It was actually quite interesting. I learned a lot about the safety policies and procedures along with what to do if an unsafe situation were to arise. Originally an event […]

Read MoreSince I became part of the oil and gas industry, natural gas processing specifically, I have wondered about natural gas vehicles. I came into this knowing there are a few out there, but I want to know more. How expensive are they? Where can you refuel them? Is maintenance on them the same as a […]

Read More