Cameron P. Croft

Founder and CEO

Mr. Croft graduated from the University of Houston with a Bachelor of Science in Mechanical Engineering Technology and holds a Master of Science in Technology Project Management with a black belt in Lean Six Sigma. Since 2006, Mr. Croft has served as the founder/CEO of several other natural gas processing companies including Croft Production Systems and Croft Supply. In 2019, Mr. Croft established the Surplus Energy Equipment with a team of engineers that have been in the oil and natural gas industry for over 10 years. He designed this platform to allow clients to see a full line of equipment without having to make phone calls to vendors or spend time searching for quality equipment. His focus now is building relationships with partners and expanding on CROFT's product lines.

Find me LinkedIn: https://www.linkedin.com/in/cameron-p-croft/

The transition from reactive maintenance to proactive preventative service has become a game-changer in the oil and gas industry. It’s not merely a shift; it’s a strategic move that safeguards against failures, minimizes downtime, and maximizes production efficiency, ultimately translating into enhanced profitability. At Croft Production Systems, we understand preventative maintenance’s pivotal role in natural […]

Read MoreNatural gas, a vital energy source for various industries, often requires careful treatment before being transported and utilized efficiently. Dehydration is a critical process in preparing natural gas for distribution. This post delves into the fascinating world of Tri-ethylene Glycol (TEG) systems, a standard method for natural gas dehydration. We explore the importance of this […]

Read MoreHydrogen Sulfide (H2S) is a highly toxic gas that poses severe risks to personnel and can cause numerous issues throughout the oil and gas production process. To address the detrimental effects of H2S, it is crucial to remove this gas efficiently. Croft Production Systems offers two effective solutions for H2S removal: their Amine Plant (GSS) […]

Read MoreNeedville, Texas, May 23, 2023 – Croft Production, a leading energy equipment, and solutions provider, is pleased to announce its portfolio expansion and diversification with the introduction of advanced technologies for drilling and eFracking gas units. These innovative solutions help operators save on operational costs while promoting environmental sustainability. The drilling industry is constantly seeking […]

Read MoreAcid gas is a type of natural gas that contains significant quantities of hydrogen sulfide (H2S), carbon dioxide (CO2), or similar acidic gasses.

Read MoreAs I learned more about natural gas, I started to be curious about where it all started. How did we even find natural gas? How did we know what it could be used for? Natural gas is essential and used daily for things such as heating, stove tops, water heaters, etc. I thought it would […]

Read MoreThis virtual roundtable discussion explores topics related to processes and equipment used in CO2 and H2S removal.

Read MoreThis virtual roundtable discussion explores topics related to processes and equipment used in CO2 and H2S removal.

Read MoreAs the push for sustainable energy is becoming increasingly renowned, companies are taking stock in how they can contribute to its demands, leading to a rise in renewable natural gas.

Read MoreThis virtual roundtable discussion explores topics related to processes and equipment used in CO2 and H2S removal.

Read MoreThis virtual roundtable discussion explores topics related to processes and equipment used in CO2 and H2S removal.

Read MoreThis case study will focus on treating fuel gas for gas lifts utilizing CROFT’s Fuel Gas Conditioning System.

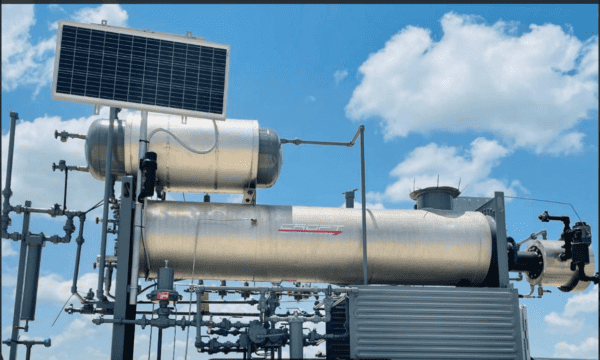

Read MoreMost customers dread having to conduct a full cleanout of a TEG dehydrator. The cleanout sometimes implies shutdowns or drop in capacity. One of the ways CROFT designed the Passive Dehydration System (PDS) is to be utilized as a quick, easy, and a temporary way to bypass a TEG and continue to dehydrate the gas while your TEG is shut down and getting serviced/cleaned out.

Read MoreThe CIS 30 MM model. This system was designed to have different static mixers to create enough turbulence and increase contact time without creating too much of a pressure differential. It has a modified two-phase separator to act as a bubble tower for efficient use of the chemical while providing proper separation.

Read Morenatural gas processing has several steps, the main processes include separation, carbon dioxide and hydrogen sulfide removal, dehydration, and NGL recovery.

Read MoreAbsorption vs. Adsorption Dehydrating natural gas, or the removal of water vapor from natural gas can be done by either adsorption or absorption. Croft’s Passive Dehydration System uses adsorption, where water vapor is collected and condensed on the surface with the use of a solid desiccant. Solid desiccants have a high adsorption capacity, a low resistance to gas […]

Read MoreGas dehydration is the removal of water from the gas stream in order to meet pipeline specifications.

Read MoreCROFT Passive Dehydration Systems natural gas dehydration unit that utilizes a specially formulated solid desiccant called enviroDRI to adsorb water from the gas stream. Below are our clients’ most commonly asked questions about enviroDRI. What is enviroDRI? enviroDRI is a deliquescent desiccant pellet about the size of an almond designed to adsorb water from hydrocarbon […]

Read MoreThe Passive Dehydration System is the preferred alternative to the glycol unit for natural gas dehydration. Dehydration is a critical process required to meet pipeline specifications.

Read MoreDual Fuel Powered Drilling Rigs and Frac Spreads Many cost-conscious oilfield companies have made the switch to either natural gas or dual-fuel, also referred to as bi-fuel, which is a mixture of diesel and natural gas. Dual-fuel engines run on a combination of diesel and natural gas, giving companies the flexibility to choose which fuel […]

Read More