In honor of Croft’s new service division in the Marcellus Shale, I would like to talk about some interesting facts about the region and how it all came about. The closest I have personally come to that area, is traveling to Virginia and wow…was it beautiful! The majority of the Marcellus Shale spans across 104,000 square miles through Pennsylvania, New York, West Virginia, and Ohio and after looking into those areas, they are just as beautiful. But as far as what is underneath all of that beautiful land is what I am here to write about today.

Reaching Natural gas in the Marcellus

Have you ever dropped your phone or a French fry in between your car seats and you can feel it, you can see it but you just can’t quite get to it? That’s how drilling for natural gas in the Marcellus region felt like up until recently. In the past, it was no secret that there were plentiful amounts of natural gas in the Marcellus shale. The problem was how to get to it. There was much excitement when finding large pockets of natural gas but unfortunately, there was no feasible economical way to recover these pockets especially in the 1980s when gas prices were so low. When they would reach these pockets, the gas flow would die down quickly so drillers began to ignore them when they found them.

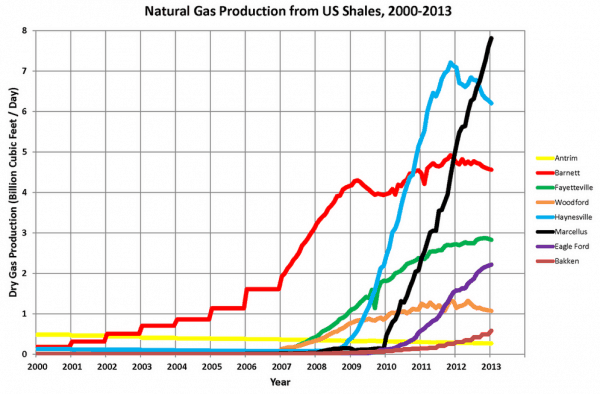

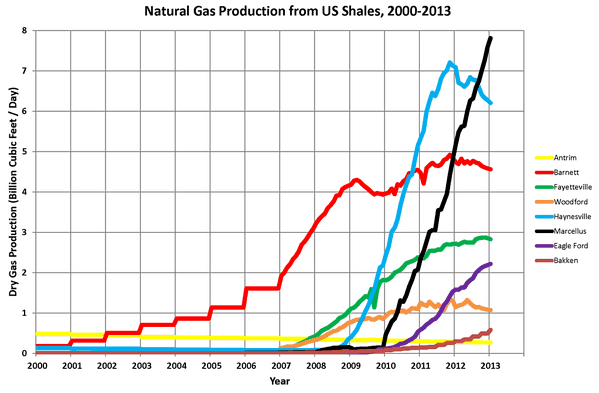

The reasoning of why they were unable to get to these large amounts of natural gas is because the Marcellus region is an example of shale gas. In a brief definition, shale gas can be defined as gas that is trapped in a low-permeability shale. The only way to recover this gas is to use the method of horizontal drilling and hydraulic fracturing (fracking) when drilling to allow the gas to flow to the well bore. This all began in 2008 and has since been viewed a modern day gold rush due to the generous amounts of natural gas that has been recovered.

Economic Wonders for the Marcellus REgion

Economically, this has been huge for the Marcellus region. In 2005, only four wells were drilled in Pennsylvania. By 2010, there were 1,446 wells and today, there are over 7,000. Needless to say, once the fracking boom hit, natural gas production took off like rocket fire. The Marcellus is currently the largest source of natural gas in the United States. This has also created local revenue and increased the creation of jobs. The industry has brought in over $11.2 billion in local revenue and has created over 139,000 jobs. Although this has done economic wonders for the region, it has also stirred up some controversy.

Now, the Controversy…

Many feel that all of the benefits that have come out of drilling for natural gas is not worth the environmental risks it has imposed. People are concerned about things such as spills, wastewater disposal, water contamination, emissions, and negative impacts that fracturing causes. In response, these states have imposed many regulations and taxes to help decrease the environmental impact as much as possible and help regulate the drilling and production of natural gas. Out of these and even out of the nation, Pennsylvania is among the strictest of these regulations. For example, in Pennsylvania it costs on average of $1 million more than its costs in other states mostly due to regulations and permitting.

Fracking is not federally regulated but instead regulated by state governments due to federal agencies being forced to give up power to individual state governments. In America, Pennsylvania has some of the most comprehensive and multi-layered fracking regulations as compared to other states.

CROFT Production Systems designs maintain and manufacture natural gas processing units that can help with some of these strict regulations. For example, our Passive Dehydration System, a dry desiccant dehydrator releases zero operational emissions and requires no air permits which is a strict regulation in Pennsylvania.

http://en.wikipedia.org/wiki/Marcellus_Formation#Natural_Gas

http://energyfactspa.com/natural-gas/page/pas-natural-gas-boom

http://en.wikipedia.org/wiki/Marcellus_natural_gas_trend

http://stateimpact.npr.org/pennsylvania/drilling/

http://www.pittsburghquarterly.com/index.php/Marcellus-Shale/show-me-the-money.html