In last week’s blog I touched on the 1975 ban on crude oil exports here in the United States. Writing that blog lead me to want to read up on the natural resources we are allowed to export. Naturally, I focused in on natural gas because this is what pays my bills. However, that is not the only reason why I chose to focus in on this matter.

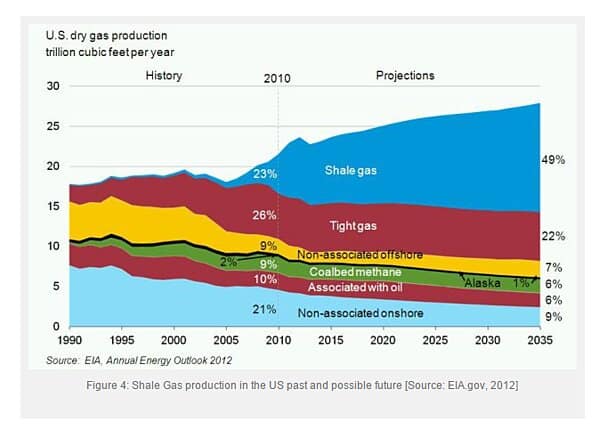

With all of the advancements in horizontal drilling and the multiple shale plays in the United States, natural gas production has truly boomed over the years. The graphic above shows just how much natural gas is being produced from shale plays and tight sand. The United States now products more natural gas than any other country. What everyone is trying to figure out now is, will it continue? With the crude production slowing down, natural gas typically follows suit. However, there some interesting projects occurring that could cause this not to happen.

So the natural resource that I am obsessing over in this blog has to be changed from a gas to a liquid in order for it to be safely transported (and it is truly safe). LNG (liquid natural gas) has been handled with care for several decades. The huge marine vessels like the picture below, have traveled more that 100,000 voyages without any major accidents or safety problems occurring. Now in order to get the gas into liquid form, this process does take some refining. In order to make this form change happen the natural gas is cooled to around -260 F. The temperature change forces the gas particles to shrink, causing the volume of the gas to decrease by about 600 times. This process creates a liquefied natural gas that is clear, odorless, noncorrosive, and nontoxic. When it is exported it is not necessary to store it under pressure and it is no longer explosive or flammable in its liquid state. It also cannot be released rapidly enough to cause over pressuring issues that are associated with explosions. Of course there is plenty of government oversight to ensure that this process continues to outside countries. The LNG industry is highly regulated by the Federal Energy Regulatory Commission, the Department of Transportation, the U.S. Coast Guard, the Department of Homeland Security, and other agencies. These regulations are in place to ensure that vessels facilities and trained personnel provide safe delivery, operations and transport.

There are some big projects that have gotten approved to supply the world with LNG from the United States. Government regulators approved the construction of two LNG plants that will process and export the money making liquid to market in Europe, Japan, Taiwan and other parts of Asia. These parts of the world have been in demand for years, due to they fact that they have been so dependent on Russia for natural gas over the years. Your head has been in the sand for a while now if you did not know that Russia is making things a bit difficult for these surrounding countries. The two main projects that have been approved are on the coast of Louisiana and Florida. These are only two of three facilities to ever get approval to export LNG here in the U.S.The terminal in Cameron Parish, LA is authorized to export up to 1.7 MMscfd of natural gas for 20 years once construction is completed in 2018. The location in Martin County, FL will be exporting 40 MMscft, though the completion day is unknown. These new projects are great news for those of us who make a living off the fracking boom in Texas, Ohio and Pennsylvania.

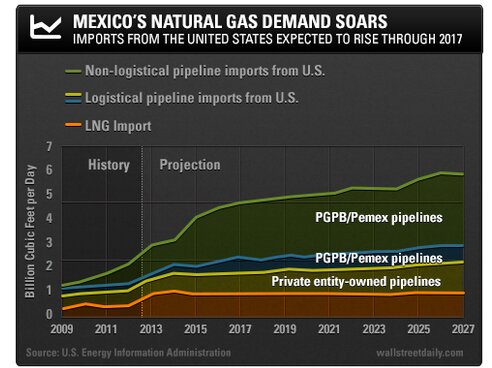

However, LNG is already making its way outside of the United Stated. Exports to Mexico have doubled from 2009-2013. Some financial groups are forecasting that the average of 1.8 billion cubic feet (bfc) of LNG that is being exported now will continue to grow to around 3.8 bcf by 2018. Again, this export will continue to help the oil and gas families working in the Permian, Marcellus, and Utica shale plays.

So what smarts did I gain this week and hopefully pass on to you? Lets recap. Exporting natural resources like liquid natural gas here in the United States is a good thing. LNG exports could add as much as $31 billion per state to gas producing places like Texas. It will keep engineering, manufacturing, construction, operating jobs, (I could keep going) here in the United States. We will be supplying power to nations around the world and keeping Americans working at the same time. The oil and gas companies do take a risk since LNG is a commodity that fluctuates in price. However, it is a risk they are willing to take.

Sounds like a win, win to me.

References:

http://www.eia.gov/tools/faqs/faq.cfm?id=268&t=6

http://www.eia.gov/dnav/ng/ng_move_expc_s1_a.htm

http://www.wallstreetdaily.com/2014/11/26/lng-shipping/

http://www.businessweek.com/articles/2014-11-06/u-dot-s-dot-natural-gas-exports-will-fire-up-in-2015

http://www.wallstreetdaily.com/2014/09/03/mexico-natural-gas/