Our Products

The transition from reactive maintenance to proactive preventative service has become a game-changer in the oil and gas industry. It’s not merely a shift; it’s a strategic move that safeguards against failures, minimizes downtime, and maximizes production efficiency, ultimately translating into enhanced profitability. At Croft Production Systems, we understand preventative maintenance’s pivotal role in natural […]

Read MoreNatural gas, a vital energy source for various industries, often requires careful treatment before being transported and utilized efficiently. Dehydration is a critical process in preparing natural gas for distribution. This post delves into the fascinating world of Tri-ethylene Glycol (TEG) systems, a standard method for natural gas dehydration. We explore the importance of this […]

Read MoreIn the oil and gas industry, natural gas dehydration plays a crucial role in ensuring safety, efficiency, and meeting pipeline specifications. Over-saturated gas can lead to corrosion, equipment damage, and non-compliance with industry standards. Gas dehydration removes excess water vapor from natural gas streams to combat these issues. In this blog post, we will delve […]

Read MoreHydrogen Sulfide (H2S) is a highly toxic gas that poses severe risks to personnel and can cause numerous issues throughout the oil and gas production process. To address the detrimental effects of H2S, it is crucial to remove this gas efficiently. Croft Production Systems offers two effective solutions for H2S removal: their Amine Plant (GSS) […]

Read MoreYannelyz: We’re back here with Chris to talk about acid and sour gas today. So Chris, what is acid gas? What is Acid Gas? Chris: Acid gas refers to a hydrocarbon stream where the components that are in the gas contain CO2 and also some amount of H2S. Yannelyz: What is sour gas? What […]

Read MoreThis virtual roundtable discussion explores topics related to processes and equipment used in CO2 and H2S removal.

Read MoreThis virtual roundtable discussion explores topics related to processes and equipment used in CO2 and H2S removal.

Read MoreGet answers to our client’s most frequently asked questions about our Fuel Gas Conditioning System (FCS)

Read MoreGet answers to our client’s most frequently asked questions about our Fuel Gas Conditioning System (FCS)

Read MoreThis case study will focus on treating fuel gas for gas lifts utilizing CROFT’s Fuel Gas Conditioning System.

Read MoreThis webinar provides education on fuel gas and JTs. Our Director of Engineering focuses on cleaning up fuel gas and getting natural gas to pipeline specification.

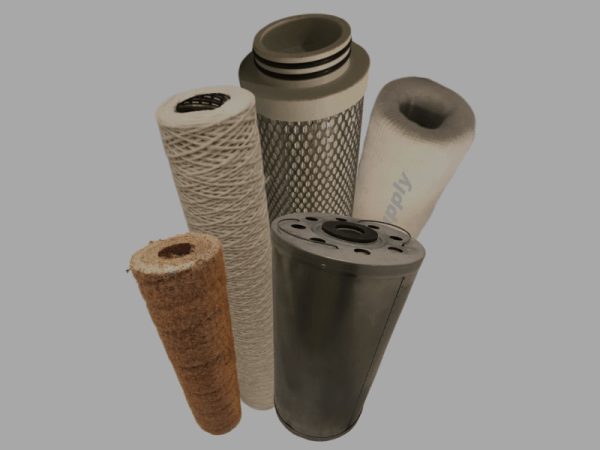

Read MoreGet answers to our client’s most frequently asked questions about filtration for amine plants, glycol dehydrators, and coalescing filters.

Read MoreThis case study will focus on optimizing filtration for amine plants and glycol dehydrators, therefore decreasing shutdown time and saving money.

Read MoreThis webinar provides education on fuel gas and JTs. Our Director of Engineering focuses on cleaning up fuel gas and getting natural gas to pipeline specification.

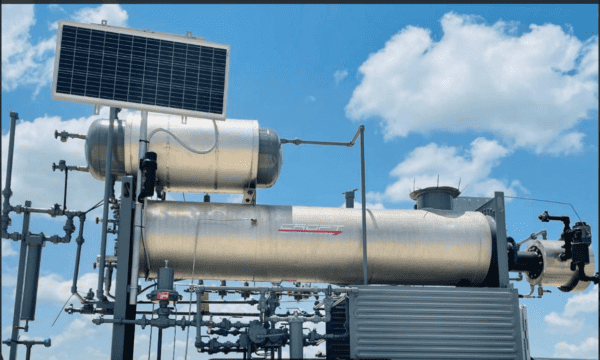

Read MoreCroft Production Systems offers skid-mounted Joule Thomson Systems that simultaneously reduces the water dew point of gas, recovers valuable hydrocarbon liquids, and lowers the BTU

Read MoreThis case study will focus on CROFTs Joule Thomson System reducing the BTU while treating gas utilized for fuel purposes in compressor engines.

Read MoreMost customers dread having to conduct a full cleanout of a TEG dehydrator. The cleanout sometimes implies shutdowns or drop in capacity. One of the ways CROFT designed the Passive Dehydration System (PDS) is to be utilized as a quick, easy, and a temporary way to bypass a TEG and continue to dehydrate the gas while your TEG is shut down and getting serviced/cleaned out.

Read MoreAmine Plant processing Acid Gas

Read MoreIn this webinar, Saving Money in Operations: Glycol Dehydration, we engage with experts discussing glycol dehydration units and optimization.

Read MoreMost customers dread having to conduct a full cleanout of a TEG dehydrator. The cleanout sometimes implies shutdowns or drop in capacity. One of the ways CROFT designed the Passive Dehydration System (PDS) is to be utilized as a quick, easy, and a temporary way to bypass a TEG and continue to dehydrate the gas while your TEG is shut down and getting serviced/cleaned out.

Read More