Preventive Maintenance Service

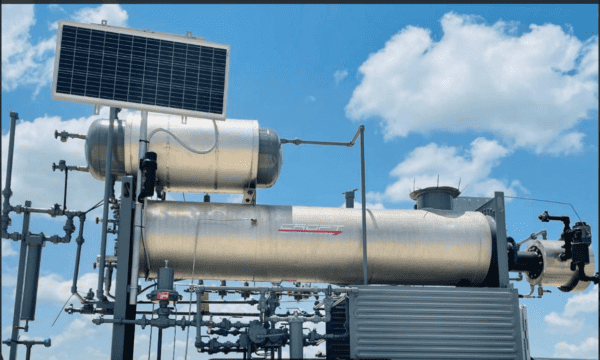

Natural gas processing equipment not being properly maintained could cost operators 10s of thousands of dollars. The costs of not servicing with professionals the equipment & plants could have liquid carryovers, diminish BTU reduction effectiveness, decreased NGL recovery, over-injection of methanol, and premature valve/part failure.

Croft offers 1st consult within the service area is free. Preventive Maintenance Service is a great way to decrease emissions, operational expenses, unscheduled downtime, chemical costs, and long-term wear and tear on equipment and increase pumps and instrumentation operational life.

Preventative Maintenance Services Include:

Keep Your System Running Smoothly

Proper maintenance of your processing equipment is essential for several reasons:

Schedule Your Preventive Maintenance Service

Schedule a Preventive Maintenance Service and conduct the multi-point inspection and make necessary adjustments for optimization and replacing any non-working instrumentation or controllers. Charge on an hourly rate and parts, mileage, per diem. Output from the report will be with necessary engineering recommendations and potential efficiency upgrades sent to the client for approval.

multi-point inspection will cover several areas such as valve sizing, controller operations, methane leak detection, processing optimization, output analysis, and much more